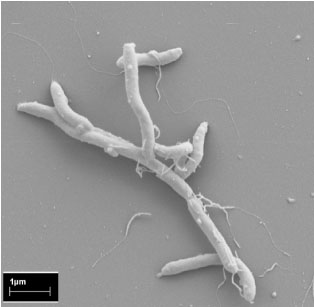

Thermoanaerobacter pseudoethanolicus 39E is the new name for Thermoanaerobacter ethanolicus 39E (as of 5/31/07). Thermoanaerobacter pseudoethanolicus, a thermophilic anaerobic bacterium (1), ferments a wide range of hexose and pentose sugars, as well as starch and pullulan, to ethanol (2, 3, 4). The organism expresses amylase and pullulanase enzymes (5) under a variety of conditions, and the optimal growth temperature is approximately 65°C. T. pseudoethanolicus can also carry out iron reduction at elevated temperatures (6). Due to the ability to efficiently ferment pentoses, T. pseudoethanolicus has been proposed as a means for the production of industrial alcohol (7) and has an approximate yield of 0.40 g of ethanol per g of xylose in batch or continuous culture (xylose comprising up to 25% of lignocellulosic materials). Economic analyses have shown that efficient fermentation of hemicellulosic sugars to ethanol by T. pseudoethanolicus or related Clostridium strains could have a large impact on the overall viability of the lignocellulosic bioconversion process. References: 1. Lee, Y.-E., M. K. Jain, C. Lee, S. E. Lowe, and J. G. Zeikus. 1993. Taxonomic distinction of saccharolytic thermophilic anaerobes: description of Thermoanaerobacterium xylanolyticum gen. nov., sp. nov., and Thermoanaerobacterium saccharolyticum gen. nov., sp. nov.; reclassification of Thermoanaerobium brockii, Clostridium thermosulfurigenes, and Clostridium thermohydrosulfuricum E100-69 as Thermoanaerobacter brockii comb. nov., Thermoanaerobacterium thermosulfurigenes comb. nov., and Thermoanaerobacter thermohydrosulfuricus comb. nov., respectively; and transfer of Clostridium thermohydrosulfuricum 39E to Thermoanaerobacter ethanolicus. Int. J. Syst. Bacteriol. 43:41-51 2. Lynd, L. R. 1989. Production of ethanol from lignocellulosic materials using thermophilic bacteria: critical evaluation of potential and review. Adv. Biochem. Eng. 38:1-52 3. Wiegel, J., L. H. Carriera, C. P. Mothershed, and L. G. Ljungdahl. 1983. Production of ethanol from biopolymers by anaerobic, thermophilic and extreme thermophilic bacteria. II. Thermoanaerobacter ethanolicus JW200 and its mutants in batch cultures and resting cell experiments. Biotechnol. Bioeng. Symp. 13:193-20 4. Wiegel, J., and L. G. Ljungdahl. 1981. Thermoanaerobacter ethanolicus gen. nov., spec. nov., a new, extreme thermophilic, anaerobic bacterium. Arch. Microbiol. 128:343-34 5>Mathupala SP, Lowe SE, Podkovyrov SM, Zeikus JG. 1993. Sequencing of the amylopullulanase (apu) gene of Thermoanaerobacter ethanolicus 39E, and identification of the active site by site-directed mutagenesis. J. Biol. Chem. 268:16332-44 6. Zhou J, Liu S, Xia B, Zhang C, Palumbo AV, Phelps TJ. 2001. Molecular characterization and diversity of thermophilic iron-reducing enrichment cultures from deep subsurface environments. J. Appl. Microbiol. 90:96-105 7. Lacis LS, Lawford HG. 1991. Thermoanaerobacter ethanolicus growth and product yield from elevated levels of xylose or glucose in continuous cultures. Appl. Environ. Microbiol. 57:579-585 |

||

|

||

Thermoanaerobacter pseudethanolicus 39E, ATCC 33223